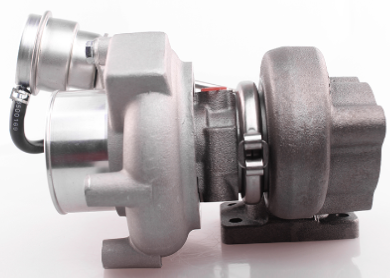

- TD04

- 49377-01611

- 8208818100

Description

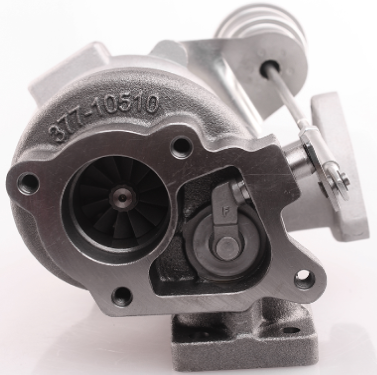

APPLICATION:Turbocharger TD04L-10GK-7.0 6208-81-8100 49377-01611 49377-01610 for Komatsu PC130-7 Excavator with 4D95LE Engine

NOTE: This turbocharger package also comes with the gaskets.

Available in stock

Packing Customized packing.Carton.Wooden case.Pallet

Shipping support Express.Air freight.Sea freight

Warranty

All turbochargers have ONE YEAR warranty.

How TD04L Turbo Komatsu Excavator PC130-8 4D95LE Engine 49377-01611 works:

The general structure of the TD04L Turbo Komatsu Excavator PC130-8 4D95LE Engine 49377-01611, the exhaust gas turbocharger is mainly composed of a pump wheel and a turbine, and of course there are some other control elements. The pump wheel and the turbine are connected by a shaft, the exhaust gas discharged from the engine drives the pump wheel, the pump wheel drives the turbine to rotate, and after the turbine rotates, the air intake system is pressurized.

The supercharger is installed on the exhaust side of the engine, so the working temperature of the supercharger is very high, and the speed of the rotor of the supercharger is very high when it is working, which can reach hundreds of thousands of revolutions per minute, such a high speed and temperature The common mechanical needle roller or ball bearing cannot work for the rotor, so the turbocharger generally adopts a fully floating bearing, which is lubricated by oil, and the coolant is used to cool the supercharger.

A gasoline engine is different from a diesel engine. It is not air that enters the cylinder, but a mixture of gasoline and air, which is prone to detonation if the pressure is too high. Therefore, the installation of a turbocharger must avoid detonation, which involves two related issues, one is high temperature control, and the other is ignition timing control.

The automotive turbocharger consists of three parts: a centrifugal compressor, a radial turbine and an intermediate. The supercharger shaft is supported in the intermediate body by two floating bearings. There are oil passages in the intermediate body to lubricate and cool the bearings, as well as sealing devices to prevent oil from leaking into the compressor or turbine.

Basic parameters of TD04L Turbo Komatsu Excavator PC130-8 4D95LE Engine 49377-01611:

Part Number: 49377-01611

Previous Part Number: 49377-01610, 4937701610

OE Number: 8208818100, 6208-81-8100, 6208 81 8100, 6205-81-8250, 6205818250

Description: Komatsu PC130-7, Construction, Earth Moving Excavator

Applications: Komatsu Excavator PC130-8 With 4D95LE Engine

CHRA: 49177-08540

Turbo Model: TD04L-10GK-7.0, TD04L-10GKRC-5

Engine: SAA4D95LE, 4D95LE, PC78US-6

Fuel: Diesel

Bearing Housing: 49177-20120

Back plate, Seal plate: 49135-15405 (49135-00044, 49173-22500)

Repair Kit: 49177-80410 (1401404755)

Turbine Housing: 49377-14340

Actuator: 49377-82090

Pros of TD04L Turbo Komatsu Excavator PC130-8 4D95LE Engine 49377-01611:

1. Power increase

TD04L Turbo Komatsu Excavator PC130-8 4D95LE Engine 49377-01611 can greatly increase the power of the engine without increasing the engine displacement

2. Reduce fuel consumption

The most important thing in automobile transportation is to reduce transportation costs. Turbochargers can reduce the fuel consumption per ton-kilometer by more than 40%.

3. Reduce pollution

Due to the increased air volume in the cylinder, the combustion conditions are improved, the fuel is fully burned, the purpose of reducing carbon oxides and soot particles is achieved, and the exhaust emission of vehicles is reduced, which is the best product that meets the environmental protection control requirements formulated by the state.

4. Noise reduction

TD04L Turbo Komatsu Excavator PC130-8 4D95LE Engine 49377-01611 can significantly reduce engine noise

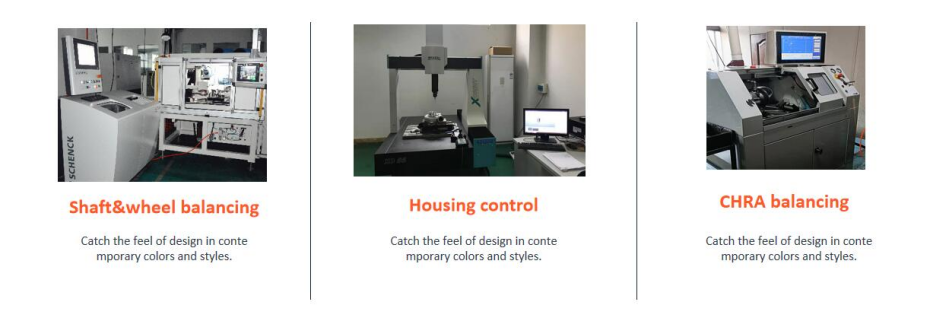

Company produces all the turbochargers and spare parts with high quality standards. Including:

– Castings are poured in ISO / TS 16949 – EN / ISO 14001 quality certified facilities, and they are regularly maintained through maintenance and calibration.

– Processes are carried out with high precision in fully automated CNC machines.

– Measurement processes are done with Zeiss 3D micron accuracy in our measuring instrument, etc.

– Balance is made at CIMAT balancing machine with 250.000 rpm,and the balancing machine with OEM approval is specially designed for passenger cars and commercial vehicles.